CHROMAL PROCESS®

20 years' experience...

CHROMAL PROCESS®, known and recognized by his costumers, made ORELEC famous : Test it, approve it !What is Chromal Process® ?

Chromal is a chrome plating part process which treats surfaces from cm² to dm².By using the techniques of electrolysis, it permits to intervene in situ on a large tool without taking it down or transporting it.

Good reasons to use this process :

- Quick and mobile,

- Efficient and sure,

- Economical.

Some pictures as examples :

ORELEC's technicians

intervene on the spot within 24hrs

troughout Europe.

Having equal qualities to chromium,

it makes the mould harder wearing

andfacilitates removal from the mould.

Quick and profitable, this process

stops the production

only for 24 or 48 hours.

It avoids costs of transport,

of dismantling and of tool’s cleaning as conventional chrome plating requires it.

intervene on the spot within 24hrs

troughout Europe.

Having equal qualities to chromium,

it makes the mould harder wearing

andfacilitates removal from the mould.

Quick and profitable, this process

stops the production

only for 24 or 48 hours.

It avoids costs of transport,

of dismantling and of tool’s cleaning as conventional chrome plating requires it.

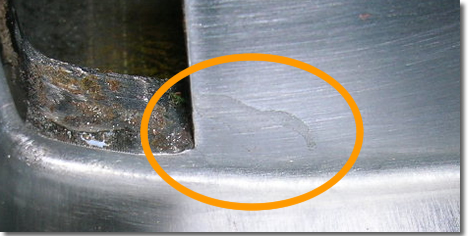

This is an example of a matrix repairing. Chromium is flaking off on a weld. Depending on the CHROMAL PROCESS, the piece is locally chrome-free treated and partially chromed again.

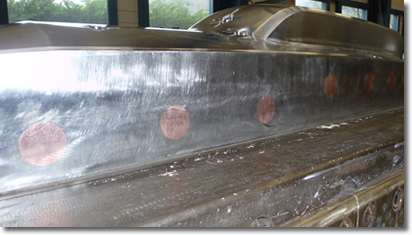

Sur cet exemple, la chambre de compression est soudée, ajustée, polie et chromée localement.